Research on Molten Salt Fast Reactors with Inherent Safety (II) - Safe shutdown without relying on control rods even in transients with safety protection system bypass -

2024.01.05

Highlights

- Molten salt fast reactors have a system to remove fission products during operation to maintain fuel.

- Analyses are performed for a molten salt fast reactor with safety protection system bypass for a reactivity accident, loss of full AC power, loss of fuel flow, and loss of heat removal function.

- Many transients cause the reactor to lower the power

- Operators are expected to take no action until 10 minutes after the accident. 10 minutes later, the reactor is safely shut down by reducing the flow rate of fuel pumps and intermediate circuit pumps to about 10%.

- Operators operate decay heat removal systems that have not been automatically activated, and the reactor remains in a safe temperature range.

- The reactor stays in a safe temperature range when the operator opens the connection valve for the decay heat removal system that has not started automatically.

- Molten salt fast reactors are significantly safer than conventional reactors due to the inherent safety of the reactor to transition to a safe mode.

Summary

For a chloride molten salt fast reactor (MSFR) system that does not require the installation of control rods, neutronics-thermalhydraulics coupled analyses under two-phase flow conditions were conducted using the system code RELAP5-3D and the CFD code FLUENT with a point kinetics model incorporated into it for events that would cause core damage without control rod insertion in a conventional nuclear reactor. As the fuel flow rate decreases during operation, the void fraction increases and a large negative reactivity is applied to the reactor with a negative void reactivity coefficient. As a result, in the event that all fuel pumps or all pumps in the intermediate circuit fail, the reactor will shut down with a sufficient safety margin, whether or not the safety protection system is activated, and enter a decay heat condition. Since the temperature reactivity coefficient is also large and negative, if the temperature rises for any reason, the reactor power will decrease. Even in the event of a large reactivity insertion that damages the fuel in a conventional reactor, the fuel temperature rise will naturally return the reactor power to near the initial power, and the operator only needs to operate the fuel pumps and cooling pump flow rate down to about 10% after about 10 minutes to shut down the reactor without problems. It is also analytically clear that the reactor system that has transitioned to decay heat can be cooled to a safe condition by natural convection of air without power.

Background

Since the Fukushima accident, molten salt reactors have attracted attention for their incomparably higher safety performance than other reactor systems, and competition for their development is ongoing in overseas. In the 1979 Three Mile Island accident and the 2011 Fukushima accident, the failure to cool the fuel caused the fuel to reach a high temperature, resulting in a core meltdown. In the Chernobyl accident, positive reactivity was added to the lower part of the core during control rod insertion, resulting in an increase in slight coolant void fraction and an even greater positive reactivity in the core, causing a reactor catastrophe. The purpose of the study is to show that molten salt reactors can remain safe even under such conventionally experienced accident scenarios. In order to remove fission products (FP) produced by fission during the normal operation, a small amount of small diameter helium bubbles is injected into the core to keep the void fraction around 0.2-0.4%. This causes little effect on the steady-state nuclear characteristics. However, as the fuel flow rate decreases, safety should be further enhanced due to the characteristics of the increased void fraction and large negative reactivity insertion into the core, making it necessary to evaluate safety under two-phase flow conditions. Molten salt reactors are already in a liquid state, can be operated under atmospheric pressure conditions, and have the property of not boiling up to about 1400-1500°C although it depends on the fuel composition. Another reason for studying MSFRs is that they can utilize spent fuels used in light water reactors, nuclear waste, and accumulated plutonium, as well as other characteristics such as converting over 99% of depleted uranium, which cannot be burned in light water reactors and is discarded, into an effective resource. Furthermore, while the safety of light water reactors and other reactors is kept from transitioning to a major accident by use of engineering safety features, MSFRs are not highly dependent on engineering safety features because of their own inherent characteristics that allow them to transition to a lower temperature condition by reducing reactor power if a higher temperature condition is reached. For this reason, it is predicted that even if a human error or an external anomaly is added to the reactor system, the transition to a severe accident is unlikely to occur.

Development competition is primarily venture-based, led by TerraPower and Elysium Industries in the area of molten salt fast reactors, and few safety details have been reported. Therefore, it was difficult to assess the degree of safety of the molten salt reactors. Although the Japanese government and electric power utilities had said that no severe accidents would occur in our country, the Fukushima accident has occurred the perception among many Japanese that nuclear reactors are extremely dangerous. However, to address global warming, research to develop MSFRs is accelerating in the United States, France, and the United Kingdom, and a molten salt reactor is already under construction and licensing status in China to convert thorium into fissionable uranium-233 for use. In the past, research on molten salt reactors has had a special history of being avoided in Japan among nuclear reactors, and little funding has been provided for molten salt reactor research. Therefore, the scale of the study is small, and we have not yet reached the point of systematically studying molten salt reactors, but we would like to clarify at least the safety aspects.

In order to realize an MSFR, it is necessary to integrate all fields of chemistry, physics, and reactor engineering, and this is a reactor type in which universities can play a major role. Currently, there are few personnel at universities who can think of nuclear reactors as a system, but the author believe that this is a good theme for rebuilding the system. It is a sincere hope of the author that many people will realize through this safety study that MSFRs are uniquely safe compared to other reactor types, and that comprehensive research will be initiated.

Research results

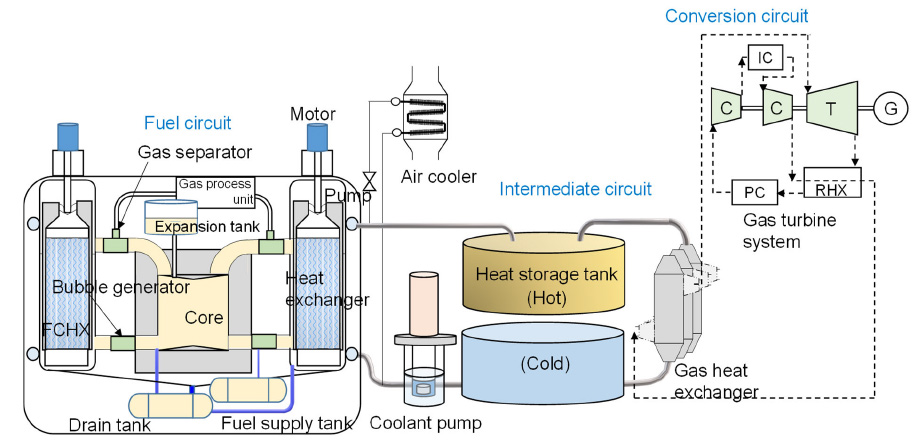

Previously, the author has proposed a point kinetics model for analyzing molten salt reactor transients and has verified that the model is correct using data from the molten salt reactor MSRE, which was built and operated in the 1960s at Oak Ridge National Laboratory in the United States. This method was used to analyze transient and accident events with the safety protection system bypass that are extremely likely to be severe accidents in conventional reactors. The MSFR under analysis shown in Fig. 1 is a chloride composition fast reactor without control rods and has a thermal power of 700 MWt. The reactor is modular in that its reactor power is regulated by the number of heat exchangers, and if studied for a single reactor, it can be used from as small as 50 MWt to as large as over 2000 MWt.

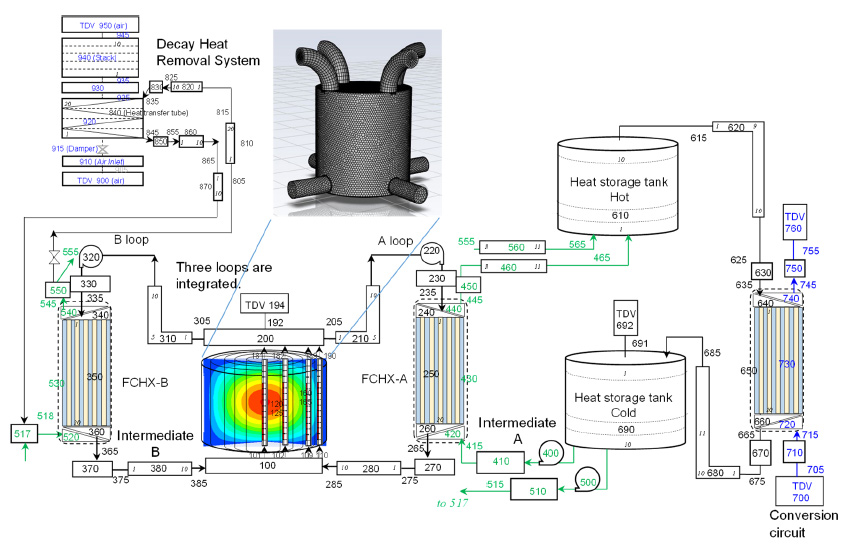

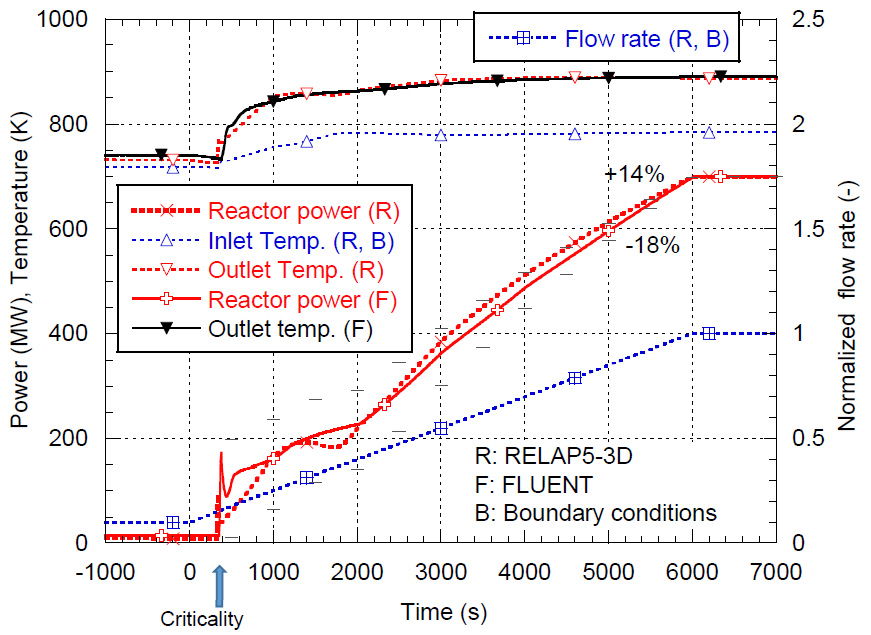

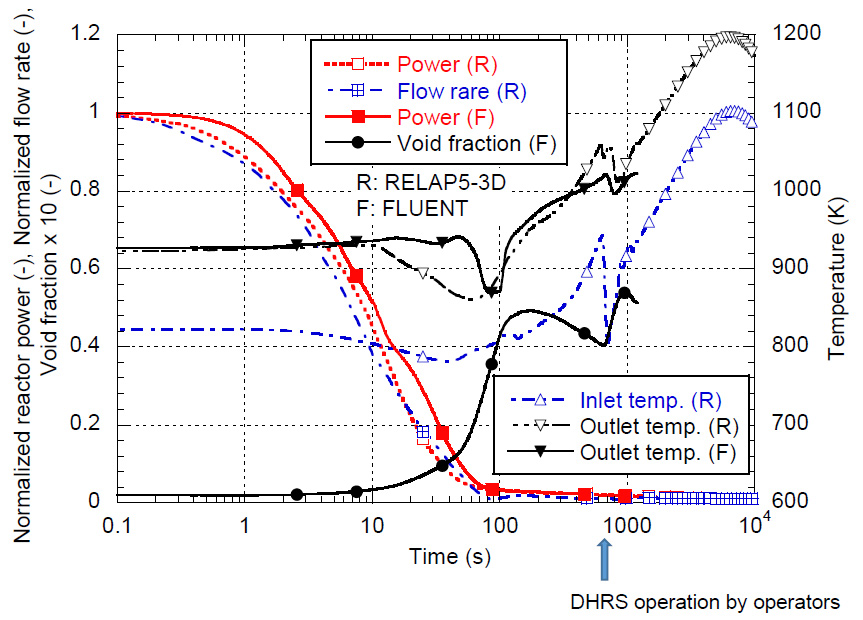

Since the reactor does not have control rods, most people will doubt that the reactor is really safe and wonder how to start it up. However, previous analyses with an analysis model shown in Fig. 2 have clearly shown that, thanks to the helium bubbles injected for FP removal, simply increasing the fuel pump flow rate from 10% to 100% of the reactor shutdown state is enough to go into criticality of the reactor, which is shut down in a decay heat condition, and further increase power (Fig. 3, original-1). In addition, even in the case of the most severe accident for a nuclear reactor, an accident in which reactivity is inserted well beyond prompt criticality, control rod insertion and rapid fuel drainage are unnecessary when the safety protection system is bypassed and the operator is not taking any action. Experiments have shown clearly that if this accident were to occur in a conventional sodium-cooled fast reactor, large mechanical energy would be generated in the reactor and the fuel would fail. The magnitude of the reactivity evaluated is much larger than that expected to be added in the case of the MSFR, but no particular problem arises. After 10 minutes, the operator reduced the fuel pump flow rate to 1/10th, which made it clear that the reactor was safely shut down thanks to the increased void fraction, and that the decay heat removal system could then be slowly activated without causing a serious accident (Fig. 4, original-2).

It was also clarified that even in the case of other accidents in which all fuel pumps stop or all pumps in the intermediate circuit stop, the reactor can be safely shut down and cooled within the safe temperature range even if the safety protection system is bypassed or the operator does not intervene.

Fig. 1. Schematic of proposed heat transfer system for molten salt fast reactor.

Fig. 2. Schematic of heat transport system analysis system in system code and CFD code analysis system.

Fig. 3. Evolution of reactor power increase from decay heat power to rated power when fuel pump flow rate is increased under reactor shutdown conditions.

Fig. 4. Evolution of core power and long-term fuel temperature behavior when all AC power is lost and safety protection systems are inoperative(DHRS: Decay Heat Removal System).

Journal information

- Journal :

- Nuclear Engineering and Design, (2023), 414, 112560, 1-16.

- Title :

- Study on Start-up of Molten Salt Fast Modular Reactor from Shutdown Based on Two-Phase Flow CFD Analysis

- Author :

- Hiroyasu MOCHIZUKI

- Affiliation :

- Laboratory for Zero-Carbon Energy, Institute of Innovative Research, Tokyo Institute of Technology

- Journal :

- Nuclear Engineering and Design, (2023), 417, 112825, 1-21.

- Title :

- Transient behavior of a molten salt fast reactor under two phase flow conditions with helium bubbling

- Author :

- Hiroyasu MOCHIZUKI

- Affiliation :

- Laboratory for Zero-Carbon Energy, Institute of Innovative Research, Tokyo Institute of Technology